Hiwin Air bearing stage - LMAS

Hiwin Air bearing stage - LMAS : Nano accuracy positioning stage developed for semiconductor/FPD industries and features air bearing of new generation.

Air bearing stage - LMAS

ดาวน์โหลดไฟล์ PDF

Feature | Air bearing stage - LMAS

Hiwin Air bearing stage - LMAS : It is leading by using vacuum preloaded air bearing with low consumption, dynamic counter balancing technology and mass compensation algorithm, which enable accurate motion in a thousandth second, decreasing production takt time. Futher-more, friction is eliminated so that equipment reliability is increased.

- Non-contact air bearing provide better positioning accuracy

- Embedded magnetic preloading design, enhance stability

- Provideextremely smooth motion and rapid setting time

- Equipped with ironless linear motor, no cogging

- High resolution feedback with linear motor, no cogging

- high resolution feedback with linear optical encoder

- Equipped with high flexi ble cable

- For clean room, no need to lubricate and easy to maintain

- Low velocity ripple

- Available for precision positioning, calibraion systems, scanning applications, wafer inspection

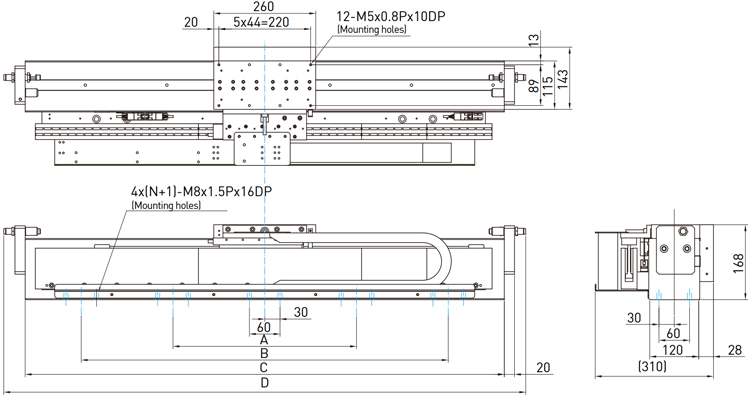

Dimensions | Air bearing stage - LMAS

| Type | Stroke | Dimensions | ||||

|---|---|---|---|---|---|---|

| A | B | C | D | N | ||

| AS200 | 200 | 280 | - | 526 | 619 | 2 |

| AS400 | 400 | 480 | - | 726 | 819 | 2 |

| AS600 | 600 | 580 | - | 926 | 1019 | 2 |

| AS800 | 800 | 440 | 880 | 1126 | 1219 | 4 |

| AS1000 | 1000 | 540 | 1080 | 1326 | 1419 | 4 |

Specifications | Air bearing stage - LMAS

| Specifications | Unit | AS200 | AS400 | AS600 | AS800 | AS1000 |

|---|---|---|---|---|---|---|

| Stroke | mm | 200 | 400 | 600 | 800 | 1000 |

| Motor type | - | LMCB8 | ||||

| Bus voltage | V | Up to 325 VDC | ||||

| Instant current | A(pk) | 6 | ||||

| Continuous current | A(rms) | 2.0 | ||||

| Feedback system | - | Optical Linear Encoder : Analog period 20µm | ||||

| Resolution*1 | µm | 4 | ||||

| Repeatability | µm | ±0.3 | ±0.4 | ±0.4 | ±0.5 | ±0.5 |

| Positioning accuracy*2 | µm | ±3.0 | ±4.0 | ±4.0 | ±5.0 | ±5.0 |

| Horizontal straightness*3 | µm | ±1.0 | ±1.0 | ±1.5 | ±2.0 | ±2.5 |

| Vertical straightness*3 | µm | ±1.0 | ±1.0 | ±1.5 | ±2.0 | ±2.5 |

| Pitch*3 | arc-sec | ±2.0 | ±2.5 | ±3 | ±3.5 | ±4 |

| Yaw*3 | arc-sec | ±2.0 | ±2.5 | ±3 | ±3.5 | ±4 |

| Roll*3 | arc-sec | TBD | ||||

| Allowable payload | kg | 10 | ||||

| Max. speed*4*5 | m/s | 1 | 1.2 | 1.4 | 1.6 | 2 |

| Max. acceleration*5 | m/s2 | 10 | 11 | 12 | 13 | 14 |

| Working pressure*6 | N/m2 | 4x105 N/m2 ± 2x104 N/m2 | ||||

| Moving unit mass*7 | kg | 8 | ||||

| Moving unit material | - | Alumimum (hardned anodized) | ||||

| Base | - | Granite | ||||

Note :

- The maximum resolution is up to 4096 times, resolution accuracy is about 4 nm

- Absolute accuracy is after error mapping.

- Required specification is restricted by load, this specification is based on empty load

- Must comply with the resolution of encoder and number of mass transfer rate

- Based on the limitations of motor instantly force, only allow moving unit mass about 8kg (center load)

- It is recommended to link pressure switch on the emergency stop devices to protect air bearing from overloading

- Free of load

Your Lift

Your Lift