| 01 |

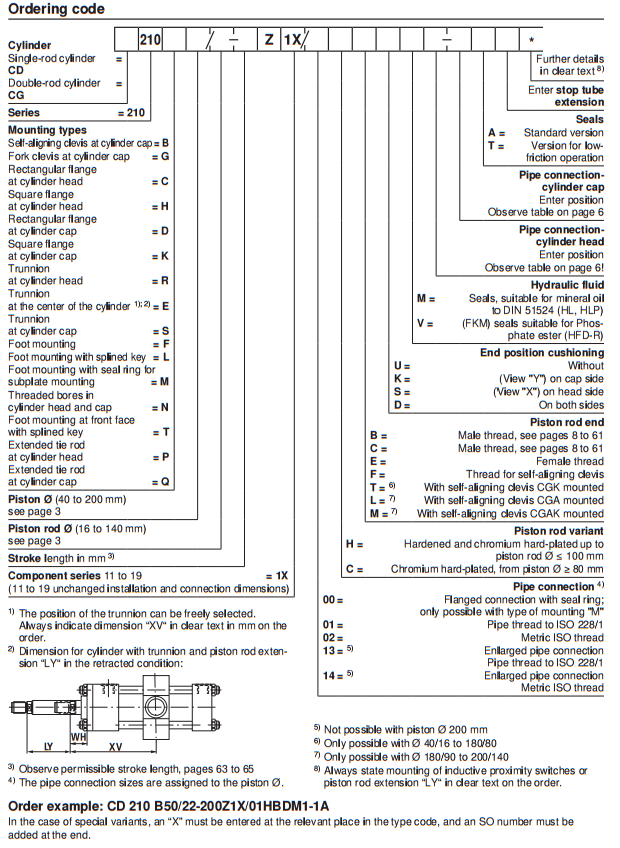

Single rod cylinder |

CD |

| 02 |

Series |

70 |

| Types of mounting |

|---|

| 03 |

Spherical bearing at cylinder base |

B |

| Fork at cylinder base |

G 1) |

| Rectangular flange at cylinder head |

C 2) |

| Square flange at cylinder head |

H |

| Rectangular flange at cylinder base |

D 2) |

| Square flange at cylinder base |

K |

| Trunnion at cylinder head |

R 1) |

| Trunnion in cylinder center |

E 3) |

| Trunnion at cylinder base |

S |

| Foot mounting |

F |

| Foot mounting with fitting key |

L 2) |

| Foot mounting with seal ring sealing for subplate mounting |

M |

| Tapped holes in cylinder head and base |

N |

| Foot mounting on front side with fitting key |

T 1; 2) |

| Extended tie rod at cylinder head |

P |

| Extended tie rod at cylinder base |

Q |

| 04 |

Piston Ø (ØAL) 25 … 200 mm |

... |

| 05 |

Piston rod Ø (ØMM) 12 … 140 mm |

... |

| 06 |

Stroke length in mm4) |

... |

| Design principle |

|---|

| 07 |

Cylinder head and cylinder base connected by tie rod |

Z |

| 08 |

Component series 11 … 19 (11 … 19: unchanged installation and connection dimensions) |

1X |

| Line connection / version |

|---|

| 09 |

Flange connection with seal ring sealing; only possible with “M” type of mounting |

00 |

| Pipe thread according to ISO 228/1 |

01 10) |

| Metric ISO thread |

02 10) |

| Enlarged line connection; pipe thread according to ISO 228/1 |

13 5; 10) |

| Enlarged line connection; metric ISO thread |

14 5; 10) |

| Piston rod design |

|---|

| 10 |

Hardened and hard chromium-plated |

H |

| Hard chromium-plated, from piston Ø ≥ 80 mm |

C 6) |

| Piston rod end |

|---|

| 11 |

external thread |

B |

| external thread |

C |

| Internal thread |

E 7) |

| Thread for swivel head |

F |

| With mounted swivel head CGK |

T |

| End position cushioning |

|---|

| 12 |

Without |

U |

| Base side |

K |

| Head side |

S |

| Both sides |

D |

| Hydraulic fluid |

|---|

| 13 |

Seals, suitable for mineral oil according to DIN 51524 (HL, HLP) |

M |

| FKM seals suitable for phosphate ester (HFDR) |

V |

| Line connection/position at cylinder head |

|---|

| 14 |

Enter position; observe the “position of the line connections” notices! View to piston rod8) |

|

1 |

| 2 |

| 3 |

| 4 |

| Line connection/position at cylinder base |

|---|

| 15 |

Enter position; observe the “position of the line connections” notices! View to piston rod8) |

|

1 |

| 2 |

| 3 |

| 4 |

| Seals |

|---|

| 16 |

Standard version |

A |

| Design for low-friction operation |

T |

| 17 |

Enter support width extension |

… |

| 18 |

Further details in the plain text 9) |

* |

Your Lift

Your Lift